NiQuan Energy does not own any technology, FT or otherwise, or process systems of it’s own. Our modus operandi, after a preliminary assessment of the opportunity, is to “right- fit” the technology and process system to the opportunity that would make the project most economically viable.

In the case of the Trinidad and Tobago Project, after a market assessment of several technologies and EPC contractors, we decided to go with Emerging Fuel Technologies (EFT) as the Technology Provider because of their history with the project; the fact that they had a prototype of our FT reactors in their lab that has been tested and proven; they were willing to provide licenses and technology guarantees; and they had a partnering agreement with Black & Veatch (B&V), that provided for B&V to do the EPC works and provide a plant performance guarantee on projects to which EFT’s technology was being used. After an assessment of Black & Veatch as the EPC contractor, it became clear that we had the right team to be successful on this project. This is a prime example of how we “right-fit” the technology and process system to the opportunity to make the project most economically viable.

FT Technology - NiQuan is using an EFT Catalyst in its FT reactor. EFT was established in 2007. They have a proto type of our FT reactor tubes in their lab in Oklahoma that has been tested and proven. EFT is a technology company focused on the development and implementation of methods for producing synthetic fuels and chemicals from a variety of carbonaceous feed stocks such as natural gas, biomass, municipal solid waste (MSW), coal and bio-derived oils. The company is one of the world’s foremost authorities on Fischer-Tropsch (FT) and related synthesis.

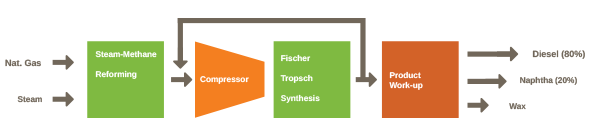

Process Systems/Units - NiQuan Energy’s plant is unique in that its existing Fischer-Tropsch (FT) reactor was constructed using converted components from methanol plants. The plant technically comprises of three (3) main process systems/units that were once in use at other various locations.

1. Synthesis Gas Generation

Natural Gas Pre-treatment

Natural Gas Reforming

Used equipment from Premcor Methanol Plant

(Delaware, USA)

Production of synthesis gas

Production of synthesis gas

2. Fischer-Tropsch Section

Synthesis Gas Compression

Compression Two (2) Fixed Bed Reactors with catalyst filled tubes.

Used equipment from Premcor and Fortier Methanol Plants

(Delaware and Louisiana, USA)

Compression of synthesis gas and production of crude methanol from Reactors with methanol producing catalyst.

Compression of synthesis gas and production of FT Wax from Reactors with FT Wax producing catalyst.

The major difference in this application is the chemistry of the reactions driven by the catalyst. This produces a different product from the synthesis gas.

3. Hydrocracking and Product Work-Up

Hydrocracker

Fractionation

Used Hydrocracker Unit

(Delaware Texaco Refinery)

Hydrocracking of crude oil products

Product distillation

Hydrocracking of FT Wax.

Product distillation.